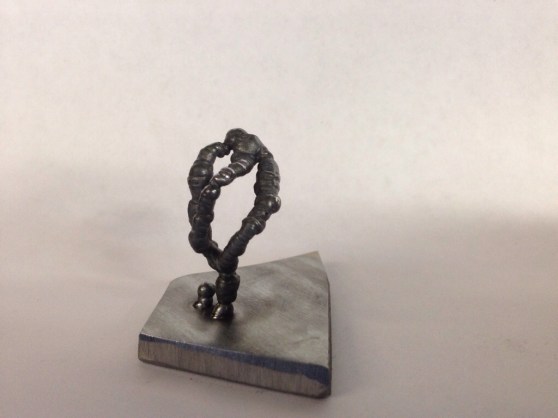

If you can build a bridge over it, you can TIG it. This piece is entitled “Grasping.” It’s interesting to see what people find in it. Dancers, chicken claws, a hand, or my personal favorite, a dejected snowman sitting under a tree.

Category Archives: Uncategorized

Fins

Underhood

A man obsessed with chrome wanted everything under the hood of his Cadillac Allante to sparkle. I prototyped and produced stainless steel covers for each of the holes under the hood. The one shown above was a test fit in traditional steel. This work required some lateral thinking to problem solve, and skills in traditional and computer drafting.

Lamp of DOOM

An exercise in architectural drafting

Freshman year of high school

Making a fixture

I had a real axe to grind that day.

Adding a pipe onto an axe or sledgehammer does two great things- adds a little more weight, and helps to extend the life of the handle. Missing and hitting the axe near the head puts a ton of stress on the handle, this protects it.

I also built up the bottom edge, which had worn away, with TIG welds, and then ground it back into shape.

Guerilla Engineering

Nothing like some cardboard, paper, sharpies, and a tape measure when it comes to designing new products!

I’m big on CAD- Cardboard aided design.

I don’t mind using computers or drafting programs, but this way is more fun, more tactile, and way more immediate.