I was proud of a particularly nice weld. It lay between each hunk of steel, puddles so tight and smooth that it looked like metal bred with liquid silk. I wanted to show it off, so I pulled off my helmet, which had no doubt left strappy sweat marks trailing through my hair, and went to where my brother, face contorted, was setting up the CNC mill. I watched the wiggler approach the shaft for a moment, then stop. I took my chance.

I asked my brother “Are you grumpy?”

He replied “I’m always grumpy. What do you need?”

“I just wanted to show you a weld that’s pretty special looking.”

As we walked over, he asked, “Does it glow in the dark?”

“It can if you give me twenty minutes. I do have that spray paint.”

He stood over the bench and examined the part. “Huh. That’s pretty nice.”

I would never expect higher praise from him.

Tag Archives: metal

An experiment in plasma

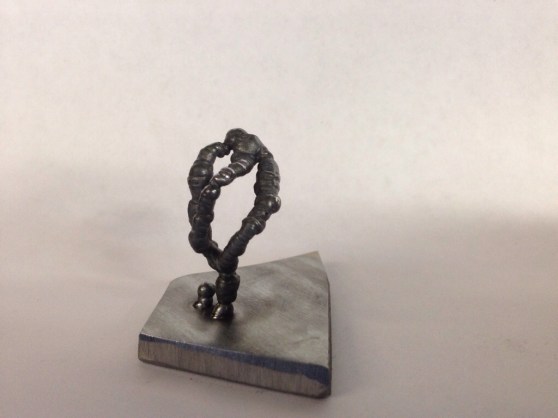

This little guy was one of the first things I made with my new plasma cutter.

Redesigned Murphy Bed

A typical Murphy bed design is incredibly large, requires you to drill holes in the wall and floor, and operates with a number of large springs. I redesigned the Murphy bed in a sleek, modern package. It is entirely self contained- no holes to drill. There is a bench available when it is in the upright position. The lift assist is performed by gas shocks, leaving the area under the bench free for storage.

It is currently on display at GRMakers and will be attending Grand Rapids Makerfaire.

To be machined away…

This is some fairly complicated aluminum welding. There is a machined channel through each piece, so the weld is between a part that is an eighth of an inch thick, and almost three quarters. The weld goes completely around the part, including a really tight inside corner followed by a curve. It must have fantastic penetration because the reinforcement is machined away and the hinge must be seamless.