I was proud of a particularly nice weld. It lay between each hunk of steel, puddles so tight and smooth that it looked like metal bred with liquid silk. I wanted to show it off, so I pulled off my helmet, which had no doubt left strappy sweat marks trailing through my hair, and went to where my brother, face contorted, was setting up the CNC mill. I watched the wiggler approach the shaft for a moment, then stop. I took my chance.

I asked my brother “Are you grumpy?”

He replied “I’m always grumpy. What do you need?”

“I just wanted to show you a weld that’s pretty special looking.”

As we walked over, he asked, “Does it glow in the dark?”

“It can if you give me twenty minutes. I do have that spray paint.”

He stood over the bench and examined the part. “Huh. That’s pretty nice.”

I would never expect higher praise from him.

Tag Archives: welding

Exposed from underneath

In process…

Because I CAN

To be machined away…

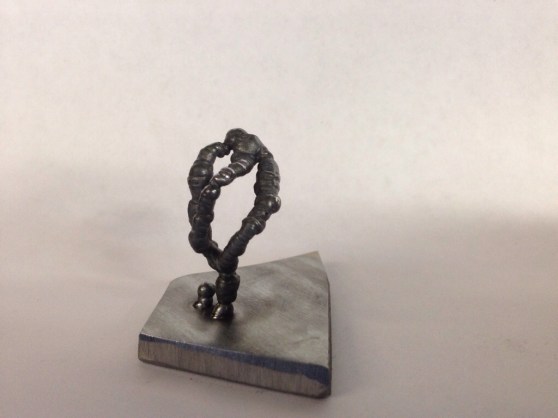

This is some fairly complicated aluminum welding. There is a machined channel through each piece, so the weld is between a part that is an eighth of an inch thick, and almost three quarters. The weld goes completely around the part, including a really tight inside corner followed by a curve. It must have fantastic penetration because the reinforcement is machined away and the hinge must be seamless.

Skeletal

Extensions

TIG welding towards oblivion…

I had a real axe to grind that day.

Adding a pipe onto an axe or sledgehammer does two great things- adds a little more weight, and helps to extend the life of the handle. Missing and hitting the axe near the head puts a ton of stress on the handle, this protects it.

I also built up the bottom edge, which had worn away, with TIG welds, and then ground it back into shape.